certified and licensed professionals

Professional gearbox maintenance and repair services ensure reliable wind turbine operation and prevent costly mechanical failures.

The gearbox is one of the most critical components in a wind turbine, converting rotor speed to generator speed. Gearboxes are exposed to high torque, variable loads, and environmental stress, which can lead to wear, overheating, and eventual failure. Timely maintenance and repair prevent unscheduled downtime, reduce repair costs, and extend turbine lifespan. Proactive gearbox maintenance and repair ensures smooth turbine operation, maximized energy production, and minimized unexpected breakdowns.

Our gearbox maintenance and repair service combines inspection, lubrication, component replacement, and performance verification to restore full operational efficiency.

Galeforce Energy provides expert wind turbine services focused on blade maintenance and repair. Our certified wind turbine service technicians handle everything from minor cosmetic fixes to full wind turbine repair, improving efficiency and extending turbine lifespan.

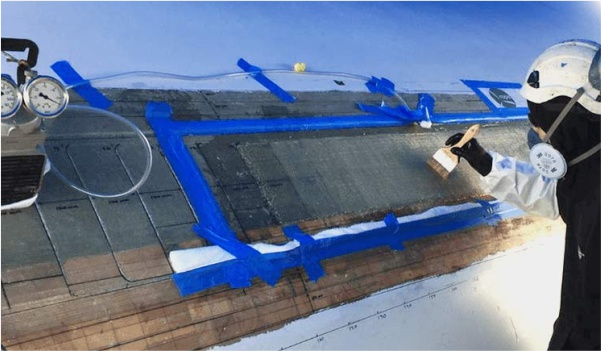

Trailing edge repairs

Our certified wind turbine service technicians repair trailing edge damages to restore aerodynamic efficiency and maximize turbine performance. These wind turbine services ensure reliable energy output across your wind farm.

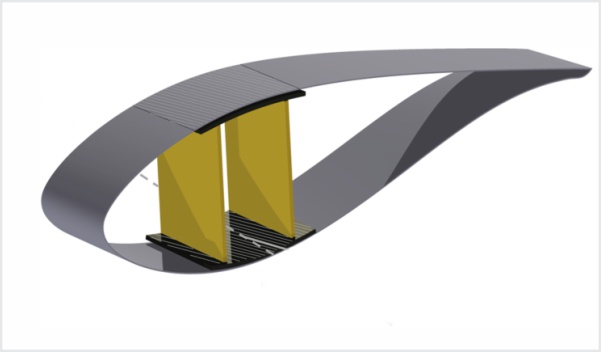

Sparcaps and Webs Repairs

Specialized wind turbine repair reinforcing essential blade components. Part of our full suite of wind turbine services for efficiency and durability.

Cosmetic Repairs

Restore blade appearance without compromising performance. Our wind turbine service technicians maintain structural integrity while providing essential wind turbine services.

Lighting strike repairs

Fast, reliable wind turbine repair for lightning damage. Our certified team ensures your turbines are back online quickly with professional wind turbine services.

External and Internal Repair

Comprehensive wind turbine repair covering both external and internal blade issues. Trust our experts to deliver precise wind turbine services for long-term reliability.

Rope Access & Platform Capabilities

Safe and efficient wind turbine services using rope access and platform solutions. Ideal for inspections, blade repair, and maintenance tasks.

Ground repair and inspection

Ground-level inspections and repairs for turbines. Critical wind turbine services for safety, efficiency, and long-term operational performance.

Drone Inspections with AI

Advanced wind turbine drone inspection captures precise images of blades and towers. Supports wind turbine repairplanning and overall turbine maintenance.

External and Internal Inspection

Our certified team performs detailed wind turbine inspection to identify internal and external issues that affect performance, safety, and turbine lifespan.

Galeforce Energy provides expert wind turbine services focused on mechanical components. Our certified wind turbine service technicians handle everything from routine wind generator maintenance and wind tower maintenance to full wind turbine repair, ensuring optimal efficiency, reliability, and long-term turbine performance.

Wind Tower Cleaning

Our wind tower maintenance includes expert cleaning to remove debris and contaminants, prevent corrosion, and maintain structural integrity as part of comprehensive wind turbine services.

Gearbox Maintenance and Repair

Full wind turbine services for gearbox inspections and repairs. Our experts maximize turbine reliability, efficiency, and lifespan.

Wind Generator Maintenance

Comprehensive wind generator maintenance and repair to optimize energy production and turbine efficiency. Delivered by certified wind turbine service technicians.

Broken Blade Stud Repair

Critical wind turbine repair to restore blade stability and operational safety. Delivered by expert wind turbine service technicians.

Vibration Analysis and Blade Balancing

Advanced wind turbine services to detect imbalances and optimize performance. Our certified technicians ensure smooth operation and reduce mechanical stress.

Structural Enhancement and Retrofits

Critical upgrades to strengthen components. Our wind turbine repair services enhance reliability and long-term operational performance.

Oil Change and Hydraulic Fluid Change

Timely maintenance of hydraulic systems, oil, and fluids. Essential wind turbine services to prevent breakdowns and ensure smooth operation.

Blade to Blade Bearing Alignment

Precision wind turbine repair aligning blades for optimal rotor performance. Our wind turbine service technicians ensure safety, efficiency, and reliable energy output.

Blade Shroud Repair

Specialized wind turbine repair for blade shrouds. Our wind turbine service technicians restore aerodynamic efficiency and protect against environmental wear.

Galeforce is a company dedicated to maintenance and repairs of wind turbines in the wind energy field. We provide rapid deployment of experienced technicians to complete tasks at hand.

gearbox maintenance and repair services

Gearboxes handle variable loads and high torque, making them susceptible to wear and tear. Regular maintenance ensures smooth operation, prevents catastrophic failures, and maintains turbine efficiency. Neglecting maintenance can lead to costly downtime and component replacement.

Routine inspection and maintenance are recommended every 6–12 months, with oil analysis performed quarterly or according to OEM guidelines. Critical monitoring can detect early signs of wear, extending gearbox life.

Repairs can resolve bearing wear, gear misalignment, seal failure, oil contamination, and vibration issues, restoring mechanical reliability and operational efficiency. Advanced diagnostics can detect faults before visible damage occurs.

Yes. Proactive gearbox maintenance and repair identifies issues early, allows planned repairs, and reduces the likelihood of unexpected failures, keeping turbines operational and energy production consistent.

Minor maintenance like oil changes and inspections may take 1–2 days, while major repairs involving component replacement can take 3–5 days, depending on accessibility and turbine size.

Yes. Technicians use precision alignment tools, vibration analyzers, thermal cameras, and oil analysis equipment to ensure accurate diagnostics and effective repair.

Absolutely. Properly maintained or repaired gearboxes reduce friction, vibration, and heat buildup, allowing the turbine to operate at optimal efficiency and maximize energy output.

Yes. Following manufacturer-recommended maintenance schedules and documenting inspections or repairs ensures compliance with OEM warranty standards and supports insurance claims if needed.

Coverage Included on every job

Through end-to-end communication, our engineers monitor each step of onsite projects. Our teams are uniquely assisted by engineers to ensure that our project performance exceeds industry standards.