certified and licensed professionals

Our advanced wind turbine inspection analysis provide fast, accurate, and safe assessments of wind turbine blades and towers.

Traditional blade inspections can be time-consuming, costly, and risky, especially at heights of 200+ feet. Detailed inspections will detect surface defects, internal delamination, erosion, and structural anomalies faster and more accurately, reducing downtime and maintenance costs. They are particularly useful for routine preventive maintenance, post-storm evaluations, and large wind farms regular inspections would be inefficient. By integrating AI-powered analysis, you can identify issues early, plan targeted repairs, and maintain optimal turbine performance.

Our inspection services combine high-resolution imaging, AI defect detection, and data reporting for comprehensive turbine evaluation.

Galeforce Energy provides expert wind turbine services focused on blade maintenance and repair. Our certified wind turbine service technicians handle everything from minor cosmetic fixes to full wind turbine repair, improving efficiency and extending turbine lifespan.

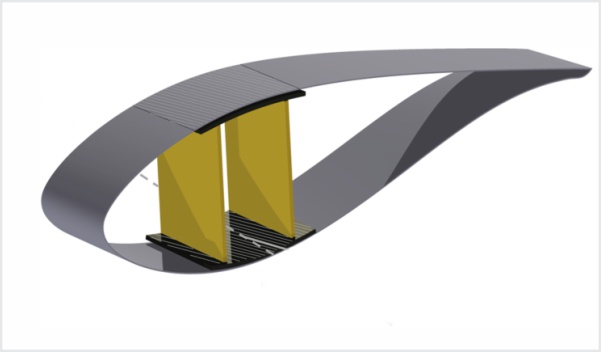

Trailing edge repairs

Our certified wind turbine service technicians repair trailing edge damages to restore aerodynamic efficiency and maximize turbine performance. These wind turbine services ensure reliable energy output across your wind farm.

Sparcaps and Webs Repairs

Specialized wind turbine repair reinforcing essential blade components. Part of our full suite of wind turbine services for efficiency and durability.

Cosmetic Repairs

Restore blade appearance without compromising performance. Our wind turbine service technicians maintain structural integrity while providing essential wind turbine services.

Lighting strike repairs

Fast, reliable wind turbine repair for lightning damage. Our certified team ensures your turbines are back online quickly with professional wind turbine services.

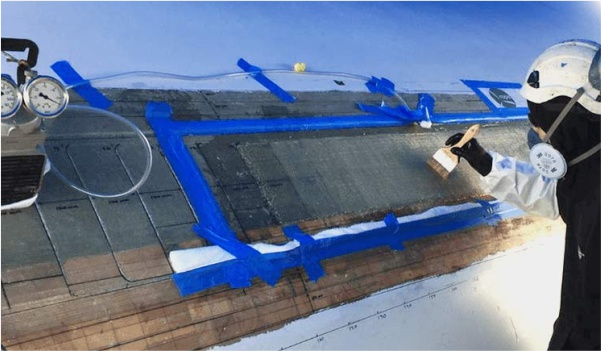

External and Internal Repair

Comprehensive wind turbine repair covering both external and internal blade issues. Trust our experts to deliver precise wind turbine services for long-term reliability.

Rope Access & Platform Capabilities

Safe and efficient wind turbine services using rope access and platform solutions. Ideal for inspections, blade repair, and maintenance tasks.

Ground repair and inspection

Ground-level inspections and repairs for turbines. Critical wind turbine services for safety, efficiency, and long-term operational performance.

Drone Inspection with AI

Advanced wind turbine drone inspection captures precise images of blades and towers. Supports wind turbine repairplanning and overall turbine maintenance.

External and Internal Inspection

Our certified team performs detailed wind turbine inspection to identify internal and external issues that affect performance, safety, and turbine lifespan.

Galeforce Energy provides expert wind turbine services focused on mechanical components. Our certified wind turbine service technicians handle everything from routine wind generator maintenance and wind tower maintenance to full wind turbine repair, ensuring optimal efficiency, reliability, and long-term turbine performance.

Wind Tower Cleaning

Our wind tower maintenance includes expert cleaning to remove debris and contaminants, prevent corrosion, and maintain structural integrity as part of comprehensive wind turbine services.

Gearbox Maintenance and Repair

Full wind turbine services for gearbox inspections and repairs. Our experts maximize turbine reliability, efficiency, and lifespan.

Wind Generator Maintenance

Comprehensive wind generator maintenance and repair to optimize energy production and turbine efficiency. Delivered by certified wind turbine service technicians.

Broken Blade Stud Repair

Critical wind turbine repair to restore blade stability and operational safety. Delivered by expert wind turbine service technicians. Get in touch and schedule your drone inspection with AI today.

Vibration Analysis and Blade Balancing

Advanced wind turbine services to detect imbalances and optimize performance. Our certified technicians ensure smooth operation and reduce mechanical stress.

Structural Enhancement and Retrofits

Critical upgrades to strengthen components. Our wind turbine repair services enhance reliability and long-term operational performance.

Oil Change and Hydraulic Fluid Change

Timely maintenance of hydraulic systems, oil, and fluids. Essential wind turbine services to prevent breakdowns and ensure smooth operation.

Blade to Blade Bearing Alignment

Precision wind turbine repair aligning blades for optimal rotor performance. Our wind turbine service technicians ensure safety, efficiency, and reliable energy output.

Blade Shroud Repair

Specialized wind turbine repair for blade shrouds. Our wind turbine service technicians restore aerodynamic efficiency and protect against environmental wear.

Galeforce is a company dedicated to maintenance and repairs of wind turbines in the wind energy field. We provide rapid deployment of experienced technicians to complete tasks at hand.

Drone Inspection with AI

Drones equipped with high-resolution cameras and thermal sensors fly around each blade and tower, capturing detailed imagery. AI algorithms then analyze these images to detect surface cracks, delamination, erosion, and lightning damage, providing actionable insights for maintenance.

AI allows for faster, more accurate identification of defects that might be missed by the human eye. It can flag early-stage damage, quantify defect severity, and prioritize maintenance tasks, reducing unnecessary downtime and repair costs.

Routine inspections are recommended every 6–12 months, with additional assessments following extreme weather events, lightning strikes, or suspected blade damage. AI-assisted drone inspections allow for quicker repeat assessments without extensive labor costs.

For many tasks, yes. Drones can safely and efficiently perform both surface and near-surface inspections. However, certain repairs or detailed internal composite assessments may still require rope access or platform intervention.

Absolutely. Flights are conducted by certified drone operators following FAA regulations and strict safety protocols. AI analysis further enhances reliability by providing consistent, objective detection across multiple turbines.

A drone inspection with AI takes more or less time depend on turbine size and number, but a single turbine can often be inspected in 30–60 minutes, with AI analysis completed shortly after flight. Large wind farms benefit from parallel inspection across multiple turbines, significantly reducing total downtime.

AI-generated reports include high-resolution images, defect mapping, severity assessment, and recommended actions, which can be integrated directly into maintenance planning or OEM compliance records.

While drones primarily detect surface and near-surface damage, AI algorithms combined with thermal imaging and high-resolution photos can indicate areas with potential internal delamination or moisture ingress, guiding targeted inspections or repairs. Our drone inspection with AI is the way to go when it comes to efficiently assessing your turbine and blades.

Coverage Included on every job

Through end-to-end communication, our engineers monitor each step of onsite projects. Our teams are uniquely assisted by engineers to ensure that our project performance exceeds industry standards. Schedule your drone inspection with AI easily.